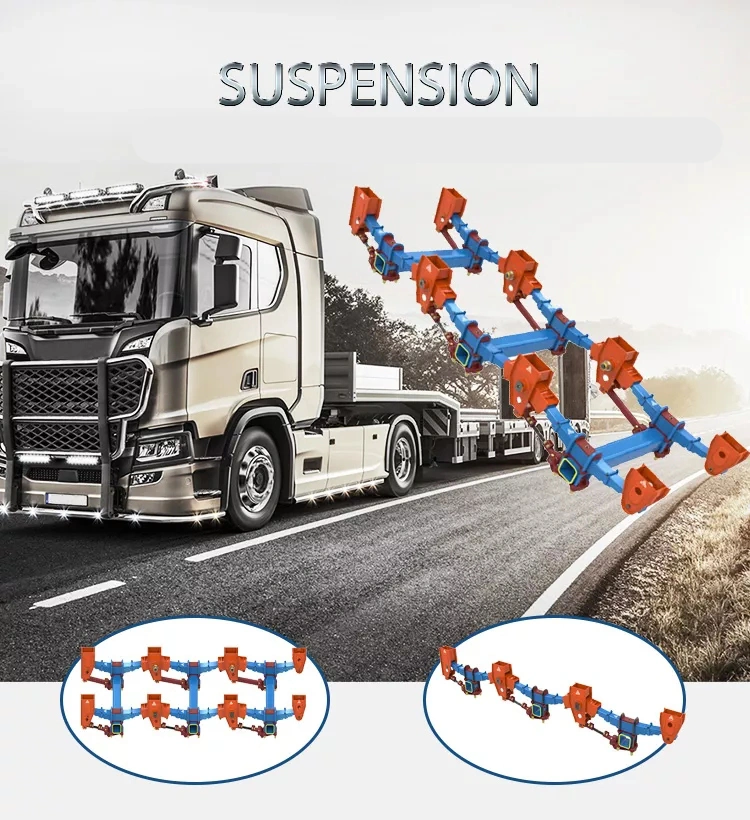

China Manufacturer Low Price Mechanical Suspension Parts 3 Axle American Type Trailer Auto Parts Suspension

Description

Basic Info

| OEM | Yes |

| Type | Suspension Spring |

| Size | OEM |

| Color | Optional |

| Application | Mechanical Suspension for Semitrailer |

| Transport Package | Standard Package |

| Specification | 2-axle/3-axle |

| Trademark | JS |

| Origin | China |

| HS Code | 87169000 |

| Production Capacity | 2000PCS/Month |

Product Description

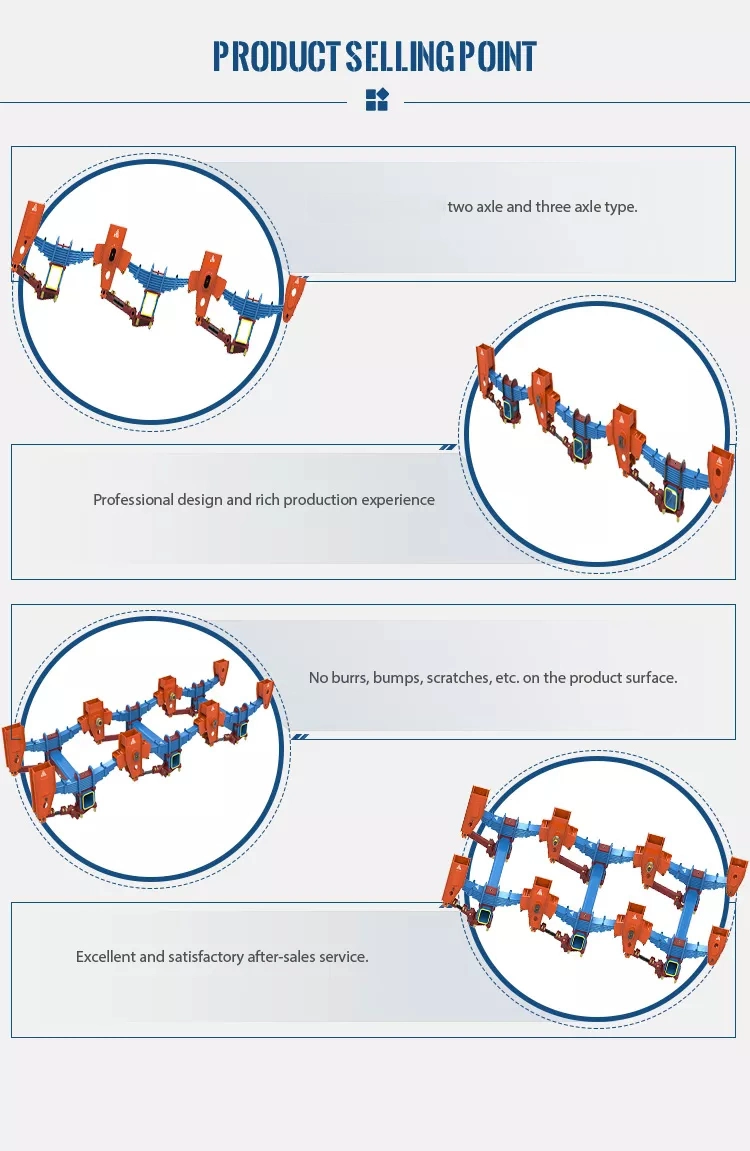

Mechanical Suspension Features: 1. Semi-trailer suspensions2.2-axle system, 3-axle system, 4-axle system, single point suspension systems are Available3.Capacity for different requirements4. Boogie according to special needs5.Has passed the ISO standard authentication of international quality control system6.Strict quality control system to assure our excellent product quality.7.products are popular in the worldwide market, including North American, South American, European, African and Southeast Asian markets.

Product Description

| Model | A1(mm) | A2(mm) | L1(mm) | L2(mm) | L3(mm) | L4(mm) | L5(mm) | H(mm) | Axle load(kg) |

| JS13.2/D130/AQ6/10 | 415 | 406 | 485 | 1310 | 495 | 1135 | 1155 | 130 | 13,000*2 |

| JS13.2/D150/AQ6/10 | 435 | 426 | 485 | 1310 | 495 | 1135 | 1155 | 150 | 13,000*2 |

| JS13.2/D180/AQ6/10 | 465 | 456 | 485 | 1310 | 495 | 1135 | 1155 | 180 | 13,000*2 |

| JS13.2/D210/AQ6/10 | 495 | 486 | 485 | 1310 | 495 | 1135 | 1155 | 210 | 13,000*2 |

| JS13.2/D230/AQ6/10 | 515 | 506 | 485 | 1310 | 495 | 1135 | 1155 | 230 | 13,000*2 |

| JS13.2/D250/AQ6/10 | 535 | 526 | 485 | 1310 | 495 | 1135 | 1155 | 250 | 13,000*2 |

| JS13.2/D270/AQ6/10 | 555 | 546 | 485 | 1310 | 495 | 1135 | 1155 | 270 | 13,000*2 |

| JS13.2/D300/AQ6/10 | 585 | 576 | 485 | 1310 | 495 | 1135 | 1155 | 300 | 13,000*2 |

| JS13.2/D320/AQ6/10 | 605 | 596 | 485 | 1310 | 495 | 1135 | 1155 | 320 | 13,000*2 |

| JS13.2/D350/AQ6/10 | 635 | 626 | 485 | 1310 | 495 | 1135 | 1155 | 350 | 13,000*2 |

Shandong Jinsheng Axle Manufacturing, founded in 2000, is a professional manufacturer of trailer axle assemblies, semi-trailer suspension systems and correlative fittings in China. We are located in Quanpu Industry Zone which is the largest production base of trailers in China, in Liangshan, the famous scenic spot. We are one of specialized enterprises in the scientific research, design, production and sale, with more than 300 skilled employees and professional designers for different areas. We adopt the domestic and international technical standards in production, accurately grasp the information of the market demand and make quick and optimal designs. In this way, our axle, suspension and other fittings have the world-class technical quality through reasonable and advanced manufacture technologies. Our advanced processing technology, first-class production line and precision CNC machining equipment from home and abroad ensure the good quality of our semi-trailer axle assemblies, suspension systems and other correlative fittings. At the same time, our annual capacity for the export of American and German semi-trailer axle assemblies has achieved 60, 000 pieces and of suspension assemblies has achieved 50, 000 sets. We obtained the ISO9001: 2000 International Quality Management System Certification in 2003 and TS16949 Certification in 2007. "First-class product quality, the meticulous and thoughtful service, and win-win cooperation" is the philosophy that we always cherish. We not only meet the domestic market demand, but also export our products to Southeast Asia, the Middle East, Latin America and other countries, enjoying a good reputation. We always regard quality as life, and client as God. We will create a brilliant tomorrow with your sincere cooperation and support.

1. What's your advantage? First we are manufacturer, we own professinal technology & quality control team; excellent team for foreign trade plus a rich expertise in trading.2. What kinds of mainly products do you manufacture? We are a professional manufacturer of trailer axle assemblies, semi-trailer suspension systems and correlative fittings in China. 3. Can you send me samples for testing? Certainly! We'd like to provide the samples free of charge, but for the freight, pls kindly bear it. 4. How long do you finish a mew product? Usually 20~35days once all information confirmed

Prev: Parabolic Leaf Spring for Trailer and Truck

Next: Air Spring Repair Bag A1643206113 for Mercedes Ml or Gl W164 1643206013 Air Suspension

Our Contact